Miniature hydrogen fuel cells are reshaping the material handling industry. Over 60,000 hydrogen-powered forklifts now operate throughout the U.S. Most people focus on larger applications, but these compact power sources have changed how businesses implement green operations.

Monthly Archives: March 2025

- Read more »

- Read more »

The electric vehicle market continues to expand rapidly due to remarkable advances in battery technology. Experts project this market will exceed $1 trillion by 2029. These changes in the automotive industry have sparked significant developments in compact machinery.

- Read more »

The numbers tell a clear story - electric equipment costs $17,073 less to operate annually than traditional hydraulic systems. Most people think hybrid versus electric choices only matter for cars and vehicles. The reality shows this decision affects equipment of all types.

Electric options are becoming more popular throughout the industry. Companies like Loxam now secure green loans worth millions, and many buyers willingly pay 25% extra for zero-emission machines. The choice involves more than just comparing purchase prices. Electric machines run with 300 fewer moving parts than hydraulic versions. Plus, battery costs have dropped 33% since 2022, which makes the financial picture change faster every day.

This piece breaks

- Read more »

Construction equipment trends are shifting dramatically, with the electric machinery market projected to reach US$126 billion by 2044. While many assume electric equipment lacks power, today's electric mini-excavators actually deliver 30-60% more digging force than their diesel counterparts.

- Read more »

Construction equipment theft costs businesses up to $1 billion annually. This makes state-of-the-art safety products more significant than ever to protect valuable machinery investments. The industry has seen remarkable advancements in equipment security and operator safety, from 360-degree visibility systems to AI-powered monitoring solutions.

Modern safety innovations are nowhere near simple anti-theft measures. Smart operator authentication, fatigue detection systems, and up-to-the-minute monitoring capabilities now enhance compact equipment's technology. These features can reshape your equipment's safety profile for 2025 and beyond.

Let's break down the must-have safety features for your compact machinery. We'll get into AI-powered solutions and share practical implementation strategies that make sense for your business.

Essential Safety Features for Modern Compact Equipment

Modern compact machinery just needs strong safety

- Read more »

Telematics solutions continue to reshape the global scene rapidly. Active construction equipment systems have reached 6.8 million units in 2023. These systems have brought remarkable changes to fleet management and reduced worksite injuries by 79% while cutting fatalities by 83%.

- Read more »

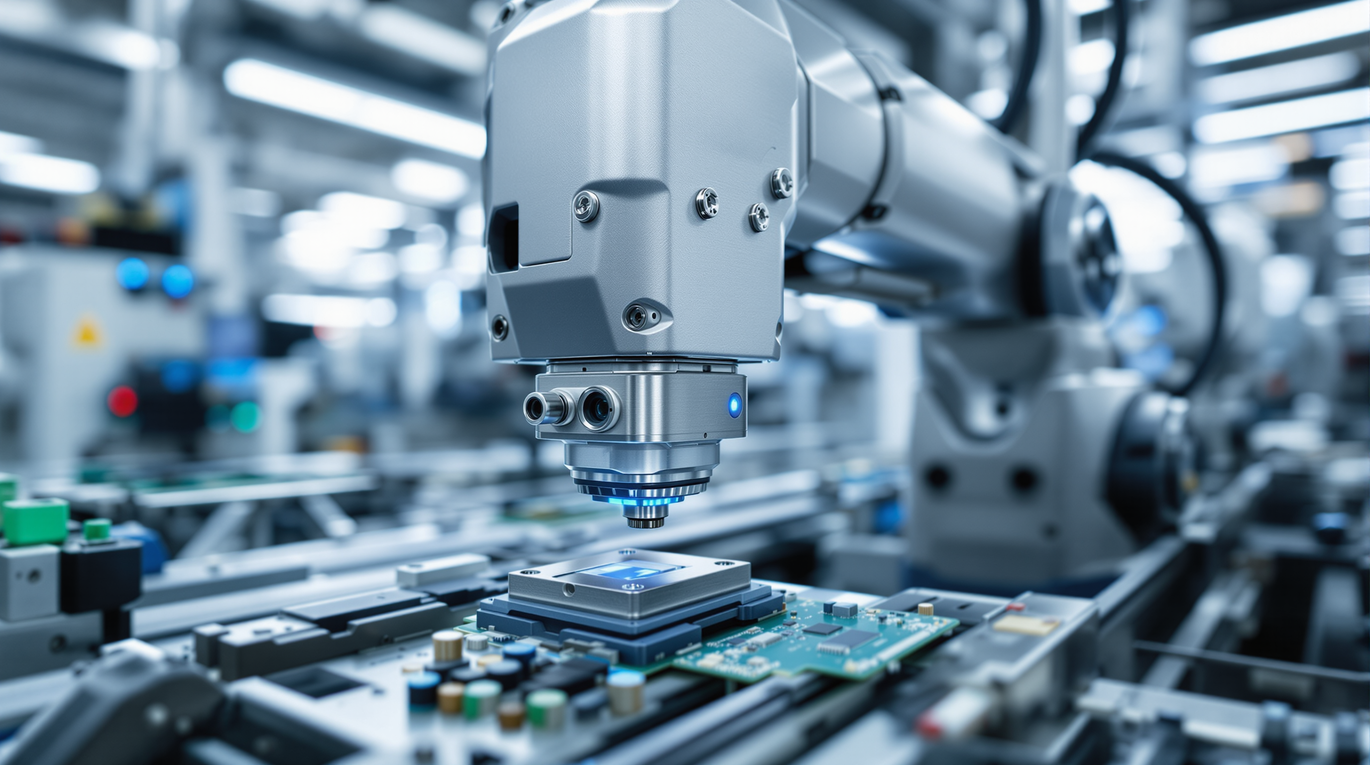

Smart sensors are revolutionizing manufacturing by reducing resource consumption by 30% to 50% in industrial applications. Our team has witnessed these advanced monitoring systems change how modern machinery operates. One electronics assembly plant reported its operational costs dropped 20% in just one year.

- Read more »

The Kubota B2601 costs between $8,000 and $27,899, which sounds like a fair deal for a compact tractor. But you need to look deeper before spending your money. This 25.5 hp diesel-powered workhorse boasts a 1,808 lbs rear lift capacity and 12-inch ground clearance. These impressive numbers don't reveal the complete picture though.